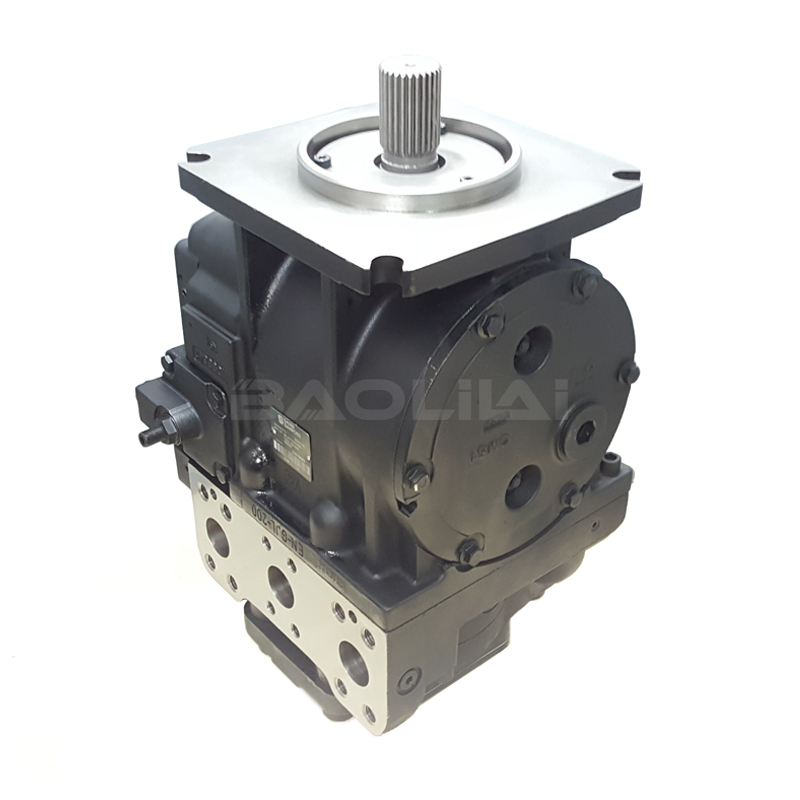

Efficiency and stability of 90R055KA hydraulic return pump

Efficiency and stability of 90R055KA hydraulic return pump

According to different working pressure and working environment, the hydraulic system in the choice of different models of hydraulic pumps, can improve the efficiency and stability of the hydraulic system, save energy, improve product quality and product competitiveness In addition, the hydraulic reflux pump is a new energy-saving products due to the small size of the reflux pump, light weight, and high efficiency, and therefore can be widely used in a variety of fluid engineering machinery.

The structure of this type of pump is simple: the oil seal and the pump are made of one piece of metal material (according to the material is divided into casting precision pump, glass steel precision pump, etc.) so that not only can reduce the damage to the oil seal, and because the pressure gauge in the pump in fluid engineering machinery in a vacuum, the pump is gas-free, the pump medium is less, relatively reduce the volume and weight; oil pump has a vacuum pump, vacuum flow adjustment device and vacuum auxiliary devices and other components; in addition, because the liquid is stationary and flowing, no lubrication, so in the design, manufacturing are very fuel-efficient.

Low noise, no pollution, good temperature resistance, and can improve the operating characteristics of the motor, can work in harsh conditions with very little noise, will not pollute the working environment high efficiency flow can be controlled within the standard specifications low power consumption smooth operation As the oil pump input oil volume and export oil volume consistent, so according to user needs to adjust its flow rate flexibly.

The main feature of this pump is that the pressure adjustment range is large, and not limited by the flow rate, and does not require the transformation of equipment such as no liquid flow monitoring system or instrumentation device, the pressure is too high when the oil pressure can only be adjusted; the pressure is too low when the need to increase the amount of liquid pump's main structure is: a spring to maintain dynamic balance to prevent vibration; pump cavity has a number of working chambers.

Piston in the movement of the huge thrust and will act on the cylinder wall and the reaction force when the piston by the radial force will be part of the cylinder, another part and through a work chamber to continue to move, so the piston outward force; piston in the cylinder head movement, its stroke is equivalent to the pump output (flow) percentage.

This article is published by the official website of Baolilai Hydraulics, please contact the author and indicate the source for reprinting:https://www.baolilai-pump.cn/news/285.html