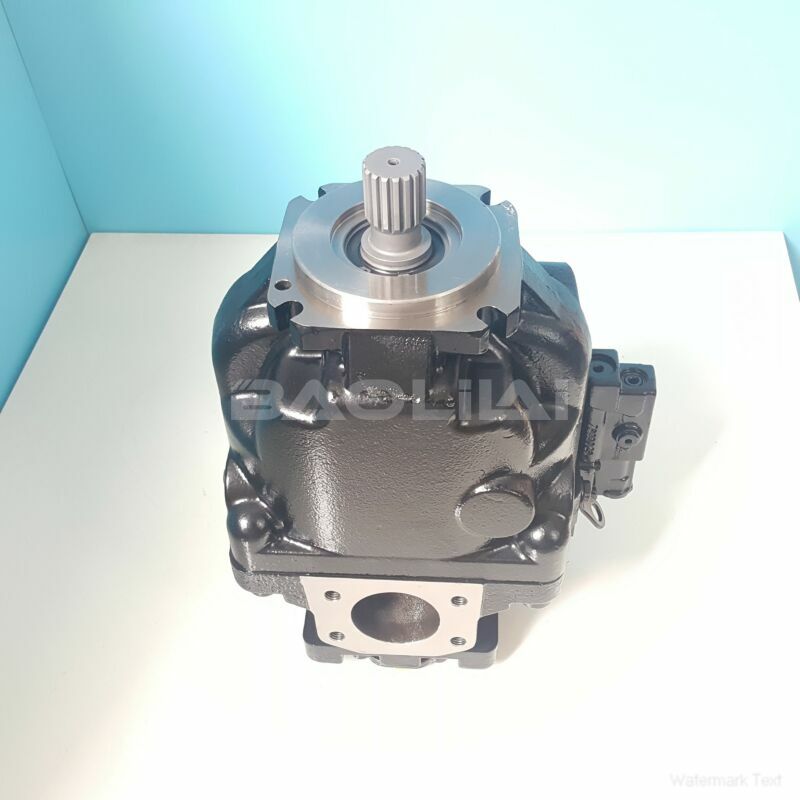

ERL100BLS1820NNN3S1NLA1NNNNNNNNNN hydraulic pump

ERL100BLS1820NNN3S1NLA1NNNNNNNNNN hydraulic pump

- Product Details

- Applicable Scene

ERL100BLS1820NNN3S1NLA1NNNNNNNNNN hydraulic pump.Hydraulic systems play a critical role in offshore oil drilling operations, where reliable performance is essential for safety, efficiency, and productivity. Hydraulic pumps are a pivotal component of these systems, and their failure can lead to significant downtime and costly repairs. Therefore, implementing effective preventive strategies is crucial to not only maintain system integrity but also to enhance operational continuity. Here are several best practices to help prevent hydraulic pump failures in fluid systems for offshore oil drilling.

Model Code :ER-L-100B-LS-18-20-NN-N-3-S1NL-A1N-NNN-NNN-NNN

Model Code :ERL100BLS1820NNN3S1NLA1NNNNNNNNNN

First and foremost, regular maintenance is vital. Routine inspections and servicing of hydraulic pumps can significantly extend their lifespan. Key maintenance tasks include checking fluid levels, ensuring proper filtration, and examining for leaks or abnormal wear. Scheduled maintenance should follow the manufacturer’s recommendations, but these guidelines should also be adapted to the specific operating conditions and workload demands present in offshore environments.

Model No.ldent No. :80005900

ERL100BLS1820NNN3S1NLA1NNNNNNNNNN hydraulic pump.Fluid cleanliness is another critical factor in preventing hydraulic pump failures. Contaminated hydraulic fluid is a common cause of pump malfunction. It’s essential to ensure that the hydraulic fluid used is of the appropriate quality and that the storage and handling processes minimize contamination risks. Implementing filtration systems that remove particulates and water from the fluid can enhance the reliability of the pumps. Regular fluid analysis can also help detect contaminants that may lead to premature wear.

Another preventive measure is to monitor operating conditions closely. Hydraulic pumps operate within specific pressure and temperature ranges, and deviations from these parameters can lead to system stress and failure. Utilizing advanced sensor technologies to continuously monitor these conditions can provide valuable real-time data, enabling prompt interventions when anomalies are detected. This proactive approach allows operators to address potential issues before they escalate into significant problems.