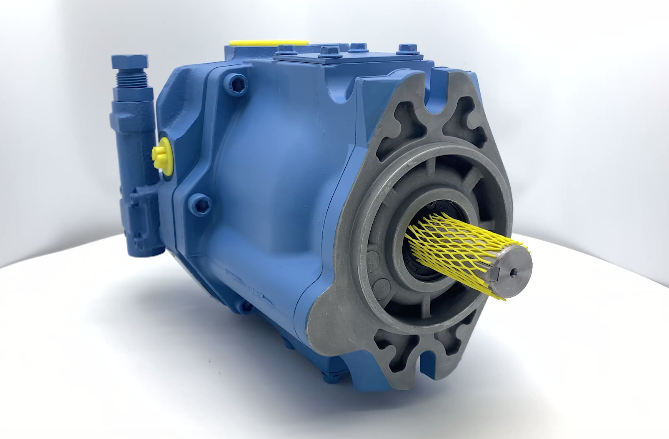

Eaton Vickers Hydraulic Piston Pump Repair

Wiggs hydraulic pump repair plunger loose boot failure. The plunger presses the slide shoe toward the thrust disk in the process of oil discharge, and pulls the slide shoe toward the return disk and away from the thrust disk in the process of oil inhalation, which is actually a continuous loose impact to the slide shoe at the skirt of the package.

Wiggs hydraulic pump repair plunger loose boot failure.

The plunger presses the slide shoe to the thrust disk in the process of oil discharge, and pulls the slide shoe to the return disk in the process of oil inhalation and breaks away from the thrust disk, which is actually a constant loose impact on the skirt of the slide shoe package. As time goes by, the bottom of the ball and socket of the slide shoe will be deformed and the material of the package mouth will be loosened and deformed due to insufficient rigidity, thus causing a gap. At this time, with one hand to grab the slide shoe, the other hand to grab the plunger before and after the up and down movement, there will be a slight "clatter" sound, and feel the axial movement can be, this phenomenon is called "loose shoe". Loose shoe is one of the mechanical failures of the axial piston pump. The reasons for loose shoe are as follows.

1, most of the loose shoe failure is in the piston pump long-term operation process gradually formed, mainly due to the operation of the oil pollution is not properly controlled due to the slide shoe and the plunger head joint part by a large number of polluting particles wedge, the relative motion between the wear.

2, congenital deficiencies. For example, the inner spherical surface of the slide shoe is not processed well, the surface roughness is too high, and after running for a period of time, the fine convex peak on the inner spherical surface is worn off, so that the gap between the plunger ball head and the plunger slide shoe of the inner spherical surface of the slide shoe is increased, and the phenomenon of loose shoe is produced.

3、It is difficult to avoid the loosening of the shoe when it has been used for a long time. Because of the long-lasting movement, when sucking oil, the plunger ball head presses the slide shoe to the stopping disk; when pressing oil, the slide shoe is pulled to the return disk thousands of times per minute, and over time, it causes the bottom of the ball socket of the slide shoe to wear out, and the bag mouth part to relax and deform, resulting in the gap, which leads to the loose shoe phenomenon.

In the process of operation, axial piston pump loose shoe, the light cause vibration and noise increase, reduce the service life of the system, the heavy make the plunger neck twist off or plunger head from the slide, so that the high-speed pump parts are broken, resulting in the whole expensive piston pump scrapped, causing serious accidents.