Sauer Danfoss variable displacement piston pump initial start-up procedure

GENERAL: Follow these steps when installing a new 45 Series open circuit pump or restarting a machine with a replaced hydraulic pump.

warn!

Accidental slippage of the machine or mechanism may result in injury to the service technician or those around. To avoid accidental movement, the machine should be immobilized or the drive mechanism disabled/disconnected during maintenance.

Before installing the pump, check for damage during transport. Make sure all system components (tanks, hoses, valves, fittings, radiators, etc.) are clean and free of contamination before adding fluid.

Sauer Danfoss variable displacement piston pump start-up procedure

1. Connect the pump to the engine, making sure the pump shaft is coaxial with the engine mounting hole.

C WARNING: Different shafts may cause damage to the drive shaft, bearings or shaft seals, resulting in oil leakage.

2. Fill the tank with the recommended hydraulic oil. Always use a 10 micron filter to filter fluid into the tank. Do not reuse hydraulic fluid.

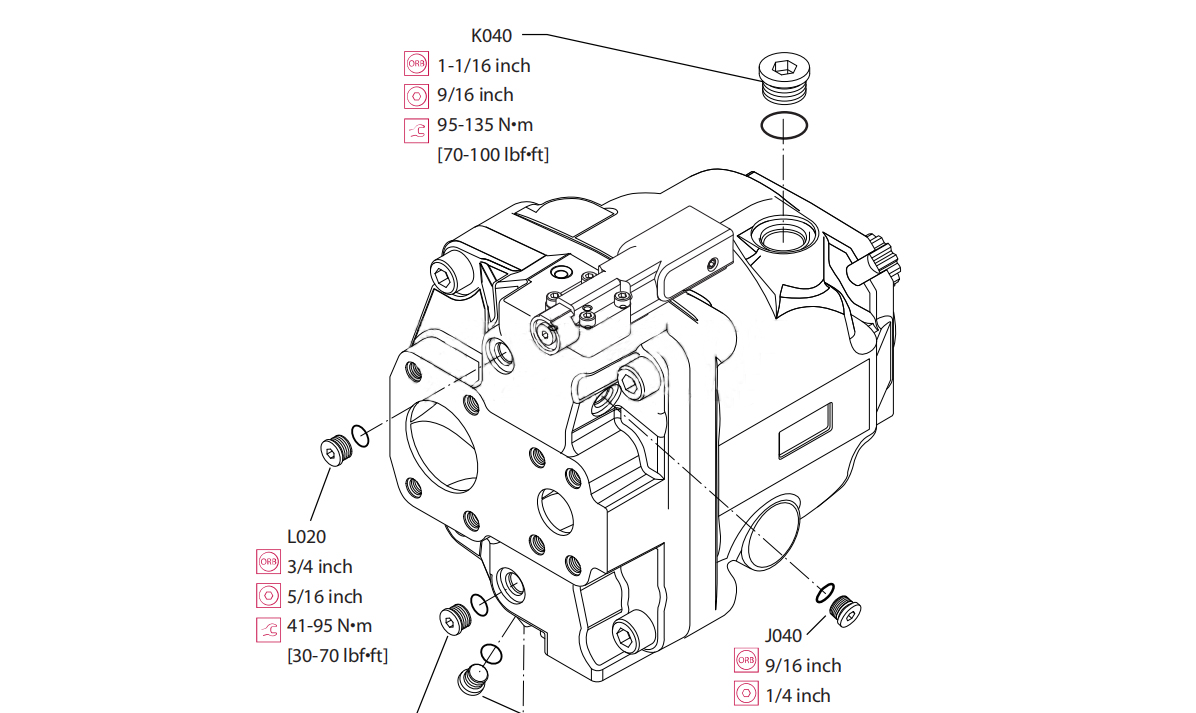

3. Fill the pump housing with clean hydraulic oil. Inject filtered oil directly into the high case drain port.

4. Fill the suction line from the tank to the pump with hydraulic oil. Check whether the pipe joint on the suction line is tightened, and the line is smooth and there is no air leakage.

5. The pump case return line is connected to the high case drain port to ensure that the pump case is always full of hydraulic oil.

6. Install a pressure gauge at the system pressure gauge port to monitor system pressure changes during startup. Engine start procedure follows vehicle/machine operating instructions

7. While watching the pressure gauge at the system pressure tap, start the prime mover at the lowest possible speed until the system pressure rises to normal (minimum 11 bar). After system pressure builds up, increase operating speed to full speed. If the system pressure is abnormal, shut down the prime mover and check

Identify the cause and take corrective action. See the Troubleshooting section.

8. Run the hydraulic system for at least 15 minutes under light load conditions.

9. Check whether the relevant pressure value meets the requirements at the rated speed, and readjust the setting if necessary. See the Adjustments section.

10. Shut down the prime mover and remove the pressure gauge. Plug the system pressure gauge port with a plug.

11. Check the oil level in the tank; add filtered oil if necessary. The pump is now ready to run.